Views: 0 Author: Site Editor Publish Time: 2025-06-02 Origin: Site

When you want to cut metal fast, high-speed cutting with advanced scrap metal shearing machines is the best. These machines make strong, steady cuts. They can cut materials like aluminum and mild steel. They work at feed rates up to 25 IPM. Their spindle speeds can go up to 4000 RPM. Hydraulic and fully automatic shearing machines are very good at fast, exact cutting. They use automation and smart technology to help.

The world market for scrap metal shearing machines is growing quickly. This is because more people want fast cutting and better metal recycling.

Automated systems help lower mistakes made by people. IoT-enabled smart shears make work even faster and more accurate.

Scrap metal shearing machines cut metal quickly. They work on thin and thick metals.Different shearing machines are good for different jobs. Hydraulic machines cut thick metal. Flying shears cut very fast for lots of metal.Automation and smart controls help shearing machines make fewer mistakes. They save time and help cut more accurately.The best cutting method depends on how thick the metal is. It also depends on if you need speed or careful cutting.Advanced shearing technology helps workers finish jobs faster. It saves money and makes cleaner cuts.

Scrap metal shearing machines come in different types. Each type is made for certain jobs and metal thicknesses. Mechanical shearing machines move fast in a full cycle. They cut thin metal sheets quickly. Hydraulic shearing machines use strong hydraulic power. They can cut thicker metal. There are swing beam and guillotine types. Swing beam machines keep the same angle and speed. This makes them good for steady cutting. Guillotine machines let you change the angle. This helps workers cut faster by adjusting the angle. Pneumatic shearing machines use air pressure. They cut fast and very accurately. Flying shear machines are the fastest. They have two plates that move in an oval shape. These are best for making lots of cuts quickly and cleanly.

Tip: Pick the right shearing machine by looking at the metal’s thickness, how fast you want to cut, and how exact you need the cuts to be.

Shearing Machine Type | Cutting Speed Characteristics |

|---|---|

Mechanical Shearing Machine | Fastest for thin metals; more strokes per minute; full-cycle operation |

Hydraulic Shearing Machine | Handles thick metals; continuous operation; swing beam (fixed speed), guillotine (adjustable) |

Pneumatic Shearing Machine | High speed and precision; best for high-precision cutting |

Flying Shear Shearing Machine | Highest speed; two plates move in an oval pattern; ideal for high-volume, clean cutting |

Hydraulic shearing machines have special features and strong cutting power. They use high-pressure hydraulic parts like pumps, valves, and cylinders. This gives them strong force and quick cutting times. Dongfang Hydraulic makes machines with up to 630 tons of force. Some can finish a cut in just 3 seconds. These machines can handle big press boxes and bale sections. They work for many kinds of metal cutting jobs.

Specification | Value |

|---|---|

Maximum Flow (Rotation Circuit) | 11 gal/min |

Apex Force | 309 Sh Ton |

Throat Force | 766 Sh Ton |

Tip Force | 175 Sh Ton |

Weight (Boom Mount) | 10,351 lb |

Jaw Opening | 22 in |

Maximum Relief Pressure (Rotation Circuit) | 2,030 psi |

Maximum Flow (Cutting Circuit) | 79 gal/min |

Maximum Relief Pressure (Cutting Circuit) | 5,075 psi |

Shear Arm Torque | 1,013,700 lb/ft |

Cycle Time (Close) | 3 Seconds |

Some features help these machines cut faster and more accurately:

Automatic blade gap adjustment gives the best space between blades.

Computer controls like PLCs and touchscreens help make cuts exact and repeatable.

Strong blades made from HSS or carbide can have their angles changed.

Energy-saving drives help the machines run faster.

Jaws can turn all the way around for easy cutting and clean edges.

Safety features include emergency stops and pressure relief valves.

Dongfang Hydraulic’s machines are built strong with tough materials. This helps them last a long time and cut well. They work for all kinds of scrap metal. Workers can cut thick or reinforced metal with high accuracy and speed.

Cutting metal fast is very important today. Different machines work better for different metals and thicknesses. Shearing, plasma, and laser cutting all have their own speeds. The table below shows how these cutting methods compare:

Cutting Technology | Cutting Speed Comparison | Operational Notes |

|---|---|---|

Shearing | N/A (no explicit speed data) | Needs several machines and workers (like 3 machines and 6 workers) |

Plasma Cutting Machines | Baseline speed (reference) | Needs extra machines and more workers; slower because of plasma arc |

Laser Cutting (10kW+) | Up to 3 times faster than plasma cutting | Can do the work of many machines with just one and two workers |

Laser cutting machines with over 10kW power are much faster than plasma cutters. They can cut up to three times quicker. This means less work for people and more metal cut in less time. Shearing machines are great for quick, repeated cuts on thin or thick metal. Plasma cutters work well on thick metal but are slower than strong laser machines.

The next table shows how each cutting machine works with different materials:

Technology | Cutting Speed Characteristics |

|---|---|

Laser | Fastest for thin metals and plastics; makes very neat edges. |

Plasma | Faster than laser on thick metals (up to 2-3 inches); edges are rougher and more heat is used. |

Waterjet | Slower than laser and plasma; does not use heat, good for thick or heat-sensitive materials. |

Router | Medium speed; mostly for wood, plastics, and light metals. |

Steel needs cutting speeds from 60 to 120 SFM. Aluminum can be cut faster, from 200 to 400 SFM. These numbers change based on tool wear, spindle speed, feed rate, and how steady the machine is. Setting these things right helps you cut fast and keep tools working longer.

How well a machine cuts metal depends on its power, how automatic it is, and the technology it uses. Dongfang Hydraulic’s shearing machines use high pressure to cut metal quickly and strongly. Automatic blade gap adjustment and computer controls help make cuts faster and more exact. These features help workers make fewer mistakes and get cleaner cuts.

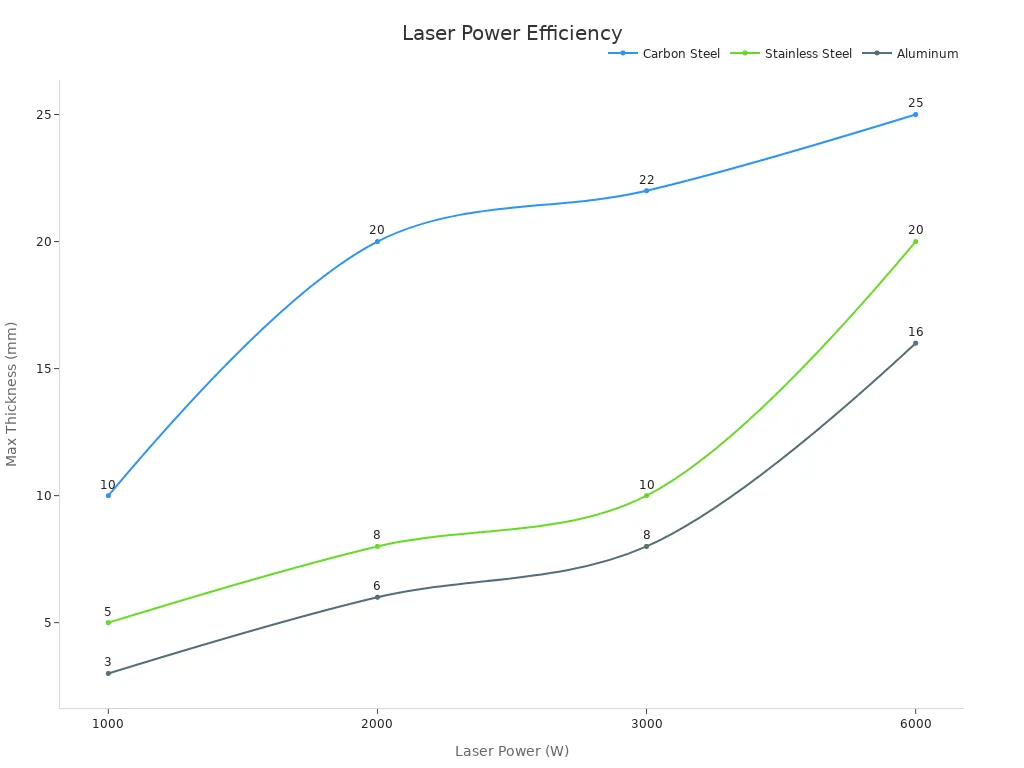

Stronger machines can cut thicker metal faster. More laser power means you can cut thicker pieces quickly. The table below shows how much metal different lasers can cut:

Laser Power (W) | Material | Max Cutting Thickness (mm) |

|---|---|---|

1000 | Carbon Steel | 10 |

1000 | Stainless Steel | 5 |

1000 | Aluminum | 3 |

2000 | Carbon Steel | 20 |

2000 | Stainless Steel | 8 |

2000 | Aluminum | 6 |

3000 | Carbon Steel | 22 |

3000 | Stainless Steel | 10 |

3000 | Aluminum | 8 |

6000 | Carbon Steel | 25 |

6000 | Stainless Steel | 20 |

6000 | Aluminum | 16 |

Automation helps by letting many machines work at the same time. Automatic loading and unloading systems save time and energy. Fast hydraulic shearing machines can cut up to 60 meters per minute, depending on the metal and settings. They can be very exact, with positioning as close as ±0.03 mm. This means less wasted metal.

Dongfang Hydraulic’s shearing machines are strong and use smart automation. They can cut many kinds of metal and different thicknesses. These machines make clean, exact cuts very quickly. They are good for places that recycle metal or process a lot of metal.

Efficiency in cutting metal is measured by machinability index, tool life, and specific cutting energy. Tests from ASTM and ISO help check these things. Using less cutting energy means better efficiency. High efficiency comes from the right mix of machine power, automation, and new technology.

Note: Picking the best cutting machine and settings helps you cut faster and better. This gives you clean, exact cuts and saves resources.

The kind of metal and how thick it is matter a lot. Harder metals and thicker sheets need more force and better machines. Hydraulic shearing machines can cut thick steel plates. Plasma cutting machines work on both thin and thick metals. The table below shows how cutting settings change surface hardness and roughness:

Cutting Parameter | Contribution to Surface Hardness (%) | Effect Direction | Notes |

|---|---|---|---|

Feed Rate | 53.41 | Increases hardness | Most critical factor for 6061 aluminum alloy. |

Depth of Cut | 27.89 | Increases hardness | Second most important factor. |

Cutting Speed | 18.7 | Increases hardness | Least impact among the three. |

Operators pick hydraulic shearing machines by looking at the metal’s thickness and how exact the cut needs to be. Plasma cutting machines can change their settings for different metals. Shearing machines give more control for straight, clean cuts.

How strong a machine is affects how well it cuts. Hydraulic shearing machines use powerful hydraulic systems. This helps them cut thick metal easily. When feed rate goes up, the machine needs more power, especially for hard metals. Sharper cutting grains help keep power use steady even when cutting faster. Dongfang Hydraulic’s machines use smart power controls. This helps them cut thick metal cleanly and with less wasted energy.

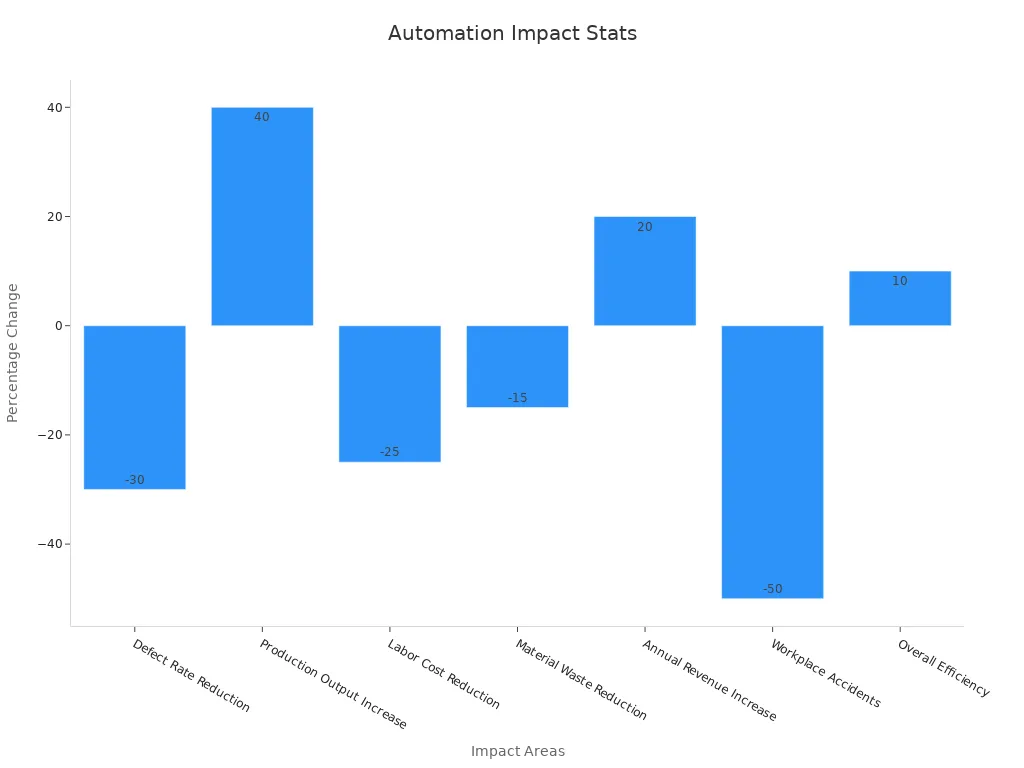

Automation and smart technology have changed how metal is cut. New hydraulic shearing machines have automatic blade gap adjustment, PLC controls, and touchscreens. These features make cutting faster, lower mistakes, and help get better cuts. The table below shows how automation helps:

Impact Area | Statistic | Explanation |

|---|---|---|

Defect Rate Reduction | 30% decrease | Automation enhances precision and consistency, reducing errors and defects in metal cutting. |

Production Output Increase | 40% increase | Continuous automated operation allows for faster and higher volume production. |

Labor Cost Reduction | 25% decrease | Automation reduces manual labor requirements, lowering labor expenses. |

Material Waste Reduction | 15% decrease | More precise cutting reduces scrap and material loss. |

Annual Revenue Increase | 20% increase | Cost savings and higher output contribute to increased revenue. |

Workplace Accidents | 50% decrease | Automation improves safety by handling hazardous tasks, reducing accidents. |

Overall Efficiency | 10% improvement | Data-driven decisions from automated monitoring help identify and resolve bottlenecks. |

Dongfang Hydraulic’s shearing machines use automation, strong power, and smart controls. These features help companies cut metal faster, more accurately, and more safely.

Picking the best way to cut metal depends on your goal. Some jobs need to be done very fast. Other jobs need very careful and exact cuts. Shearing is great when you need to cut a lot of metal quickly. Scrap metal shearing machines can cut thick metal fast. This makes them good for recycling centers and big factories. Hydraulic shearing machines can cut both thin and thick metal. This means they work for many different projects. Plasma cutting machines are best for cutting tricky shapes or thick plates. They are often used in shipbuilding and construction.

Cutting at high speed removes more metal and makes smoother surfaces. But not every job needs the fastest speed. High-performance cutting mixes fast finishing with good rough cutting. Operators must balance how strong the spindle is and how fast they cut. This helps tools last longer and keeps cuts accurate. In jobs like electronics or jewelry, laser and plasma cutting machines make the cleanest and most exact cuts.

Tip: Choose your cutting method based on how thick the metal is and how smooth you want the edge. For thick steel, use hydraulic shearing or plasma cutting machines. For thin sheets or detailed parts, use laser or high-precision shearing.

Criteria | Speed-Focused Solution | Efficiency-Focused Solution |

|---|---|---|

Material Thickness | Thick metals (e.g., ship hull steel) | Thin metals (e.g., intricate parts) |

Laser Power Range | High power (22kW to 60kW) | Low to medium power (1kW to 12kW) |

Cutting Speed | Prioritized for high volume | Balanced for energy savings |

Edge Quality and Precision | Adequate for structural parts | High precision required |

Operational Costs and Energy | Higher power use, reduced cutting time | Lower energy use, cost-effective |

Cost is very important when picking between speed and efficiency. Hydraulic shearing machines with smart controls save on labor and boost output. But cutting faster can use more power and wear out tools quicker. Plasma cutting machines are fast but may need more repairs.

A cost check shows carbide insert tools cut faster and make more parts. But they do not last as long and use more power than HSS tools. For saving money over time, think about both the price to buy and the cost to run the machine. Aluminum is easy to cut and does not wear out tools fast. This makes it cheaper for fast jobs. Hard metals like titanium take longer to cut and need special machines.

Operators should check and fix their machines often to keep them working well. Picking the right nozzle, gas, and laser power helps balance speed and efficiency. Dongfang Hydraulic has scrap metal shearing machines for both fast and careful cutting. These machines help many kinds of factories. For more information, visit Dongfang Hydraulic’s scrap metal shearing machine page.

Note: Finding the right mix of speed and efficiency helps you get the best results and save money when cutting metal.

High-speed cutting is the quickest way to cut metal. Shearing machines from Dongfang Hydraulic cut metal fast and very accurately. They work well on both thin and thick metals. Shearing removes a lot of metal quickly and saves time. Picking the right cutting method for the metal and its thickness gives the best results. Operators should change machine settings and use advanced shearing technology. They also need to choose the best way to cut for each job. Using smart cutting plans with shearing helps workers finish more jobs and work better every time.

Shearing machines are the quickest way to cut scrap metal. Dongfang Hydraulic’s machines cut fast and very accurately. They work on both thin and thick metal. These machines help recycling centers and factories cut metal quickly.

Automation makes metal cutting faster and lowers mistakes. Dongfang Hydraulic’s machines use smart controls and blade gap adjustment. These features help workers cut metal the same way every time. They also save time and lower labor costs.

Many things affect how well metal is cut. The type of metal, its thickness, machine power, and blade sharpness all matter. Dongfang Hydraulic’s machines let workers change settings for each job. This helps them get clean and exact cuts every time.

Yes, Dongfang Hydraulic’s machines can cut many thicknesses. Workers can change the settings to cut thin sheets or thick plates. This makes the machines good for many jobs in recycling and factories.

Companies can visit Dongfang Hydraulic’s scrap metal shearing machine page. The site has lots of details about strong shearing machines and other cutting tools for factories.